Dan Nienhauser, Co-Founder, CEO, and President of Stellar3, sheds light on the company’s thermal chemical conversion tech, turning landfill waste into valuable energy assets.

In the latest episode of Lexicon, Interesting Engineering’s podcast, we speak with Dan Nienhauser, Co-Founder, CEO, and President at Stellar3 — a company at the forefront of converting landfill waste into sustainable fuel.

Now, we’re all familiar with the overwhelming presence of waste in our daily lives, but what’s the broader impact of that waste beyond our own households (or businesses)? In other words, have you ever considered what happens when all our individual waste is combined with that of everyone else’s and taken to another location? Now think locally, then nationally…and then globally.

That is, a staggering 2 billion tons of waste are produced globally each year, which often ends up in landfills.

However, the repercussions of our waste extend beyond mere statistics, as most humans and animals now have detectable levels of polymers in their bloodstream, potentially leading to serious health issues.

A ‘no burning’ waste-to-energy approach

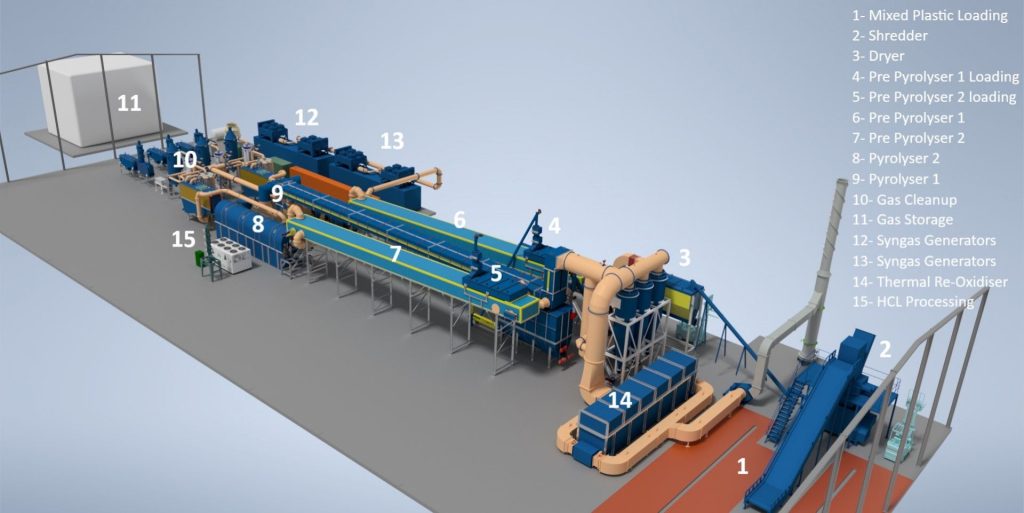

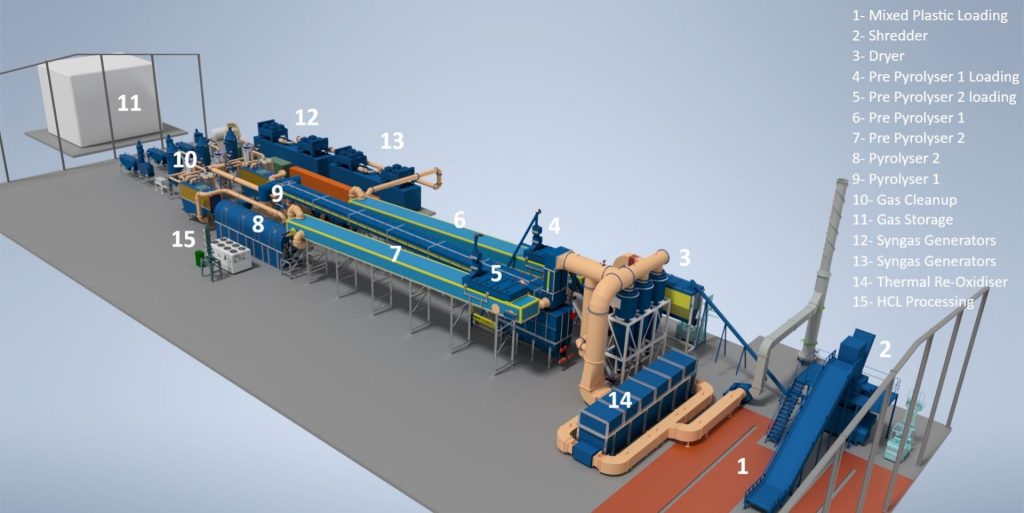

Dan Nienhauser shared insights into Stellar3’s patented Thermal Chemical Conversion technology, which transforms landfill waste, including sorted municipal solid waste, mixed plastic waste, and end-of-life tires, into valuable resources such as syngas and low-carbon liquid fuels.

The tech is also able to produce circular pyrolytic oil, recycled carbon-black, and electricity, making Stellar3’s approach of turning waste into an asset a circular one.

In our conversation with Dan, he emphasized a fundamental shift in perception, stating, “Our goals are to change the perception around waste being waste and recognize that waste is energy.”

Stellar3 plans to build one hundred waste transformation plants over the next six years, potentially saving around seven million tons of CO2 equivalent in the first phase. The ultimate aim is to expand this impact to a hundred million tons over the coming decade.

The company’s modular system is based on a paralysis process that has been around for at least a century but has advanced over the last decade. Dan explains that Stellar3’s paralysis approach efficiently converts various feedstocks into valuable products without the need for complete facility overhauls.

“This is a process where we’re using heat in the absence of oxygen — so you’re not burning anything,” he explained before stressing the importance of managing the gas, which can be condensed into liquid, to create circular or energy products efficiently.

The focus on gas management ensures a cleaner, low-sulfur liquid oil that can be utilized in various applications, from manufacturing new plastics to producing sustainable aviation fuel.

Dan explained that unlike some solutions focusing solely on chemical engineering, Stellar3’s approach incorporates thermal and chemical expertise, resulting in a robust and adaptable system.

He also highlighted the significance of thermal engineering expertise within Stellar3, differentiating it from other players in the field.

As Stellar3’s commercial plant prepares to come online in the next few weeks, he expresses excitement about the broader implications of waste transformation technologies.

“We have science that has now started to help us change the word waste,” he said, highlighting the shift from viewing waste as something to be discarded to recognizing its potential as a source of new raw materials and energy.

Benefits for local communities

Addressing waste transformation misconceptions, Dan emphasized the need for global communities to understand the difference between technologies like Stellar3’s and traditional incineration.

While incineration involves burning materials to generate heat or electricity, Stellar3’s oxygen-free environment ensures nothing burns, focusing on breaking down and rebuilding carbon without combustion.

Beyond environmental benefits, Stellar3’s waste transformation plants offer significant advantages for local communities.

Dan explained how communities sending waste to landfills can benefit from relatively affordable plants, generating electricity and eliminating 90 percent of waste that would otherwise end up in landfills.

The economic impact extends to generating new jobs and creating opportunities for security positions and engineering management.

In addition to the immediate economic benefits, waste transformation plants contribute to the overall health of communities by eliminating illegal dumps and reducing exposure to potential health hazards.

He also highlighted the potential for new industries and jobs emerging from transforming byproducts like carbon black into higher-value materials like Graphene.

A trillion-dollar annual investment

Looking ahead, Dan stressed the importance of a global commitment to waste transformation, envisioning a trillion-dollar annual investment.

With the immense volume of global waste, he emphasized the need for collaboration and scaling solutions to address the pressing environmental challenges.

“You know people [can be] focused on how to beat the other guy — but the bottom line is there’s so much waste in this world…There’s enough room for a thousand companies like Stellar3,” he said.

“We need to work together, help each other, and figure out the best way to build enough facilities to gain some traction and acceptance and then scale. Waste is an opportunity for us all.”

+ There are no comments

Add yours